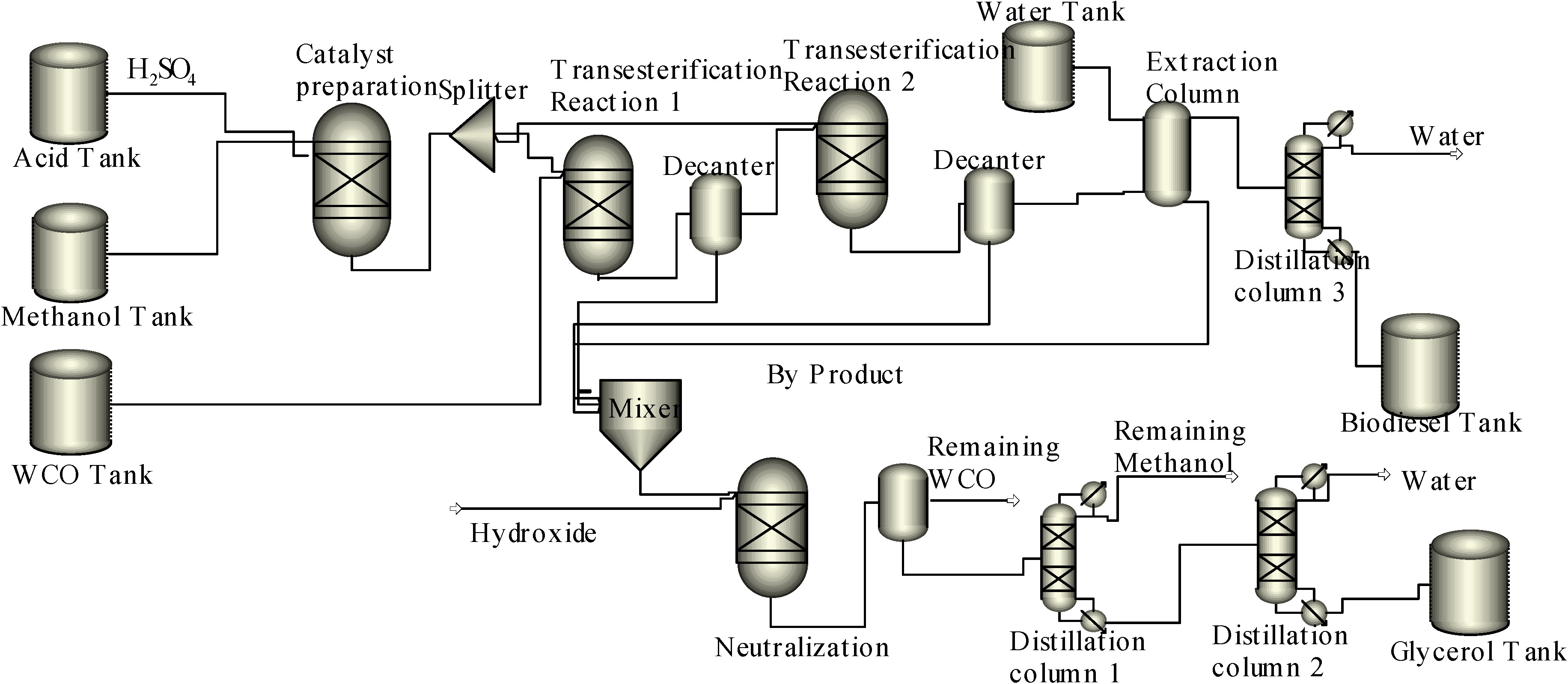

The yield percentage obtained from waste vegetable oil was comparable to that obtained from neat vegetable oil which reached 96. From the results it was clear that the produced biodiesel fuel. (The waste oil must be treated before conversion to biodiesel to remove impurities). The result is Biodiesel produced from waste vegetable oil can compete with fossil diesel. Biodiesel is typically made by chemically reacting lipids (e. , vegetable oil, soybean oil, animal fat (tallow)) with an alcohol producing fatty acid esters. Biodiesel is meant to be used in standard diesel engines and is thus distinct from the vegetable and waste oils used to fuel converted diesel engines. Biodiesel Production from Waste Cooking Oil esters monoalkyl of fatty acids of long chain that are produced from vegetable oil, animal fat or waste cooking oils in a chemical reaction known as transesterification. biodiesel production from Palm was between. Khatun et al: METHYL ESTER (BIODESEL) PRODUCTION FROM WASTE COOKING VEGETABLE OIL BY MICROWAVE IRRADIATION 322 reduce the cost of biodiesel is to decrease reaction time of transesterification and to increase biodiesel yields. Biodiesel production from vegetable oil and waste animal fats in a pilot plant Ertan Alptekina, b, Mustafa Canakcia, b, , Huseyin Sanlib, c a Department of Automotive Engineering, Faculty of Technology, Kocaeli University, Izmit, Turkey bAlternative Fuels RD Center, Kocaeli University, Izmit, Turkey cGolcuk Vocational High School, Kocaeli University, Golcuk, Turkey The oil seed source that can be used for biodiesel production in Bangladesh are WCO, mustard oil, sesame oil, coconut oil, peanut oil, linseed oil, castor oil, nahor oil etc. The high cost of biodiesel is mainly due to the cost of virgin vegetable oil. The waste vegetable oil that was used in this study was obtained from local frying houses and had an acid value of 11. 1 mg of KOHg and a moisture content of 0. However, the raw material costs and limited availability of vegetable oil feedstocks are always critical issues for the biodiesel production. The high cost of vegetable oils, which could be up to 75 of the total manufacturing cost, has led to the production costs of biodiesel becoming approximately 1. 5 times higher than that for diesel [30. Abstract The production of biodiesel from vegetable oils stands as a new versatile method of energy generation in the present there is no or very less amount of waste water produced during the process and (3) separation of biodiesel from So the production of biodiesel from coconut oil stands as a promising way of energy utilization Biodiesel can be produced from straight vegetable oil, animal oilfats, tallow and waste cooking oil. The process used to convert these oils to Biodiesel is called transesterification. This process is described in more detail below. Manufacturers of machinery for the production of biodiesel and filtration of vegetable oil. This machine will filter waste vegetable oil and remove the wax through an ingenious 4 stage process. making company and at present we sponsor this web site through biodiesel plant production contracts. The Manufacture of Biodiesel from the used vegetable oil Uni Kassel. The production of biodiesel from waste vegetable oil offers a triplefacet solution: economic, environmental and waste. blending biodiesel with petroleum diesel. The yield percentage obtained from waste vegetable oil was comparable to that obtained from neat vegetable oil which reached 96. From the results it was clear that the produced biodiesel fuel, whether from neat vegetable oil or waste vegetable oil, was within the recommended standards of biodiesel fuel. Any vegetable oil or animal fat can be used as a feedstock for biodiesel production; as these are natural products, they are mixtures of several component oils and fats. These oilsfats are triglyceride molecules (glycerin esterified with three fatty acids). Table 1: Evaluation of biodiesel yield () during ethanol, waste sunflower oil transesterification at different temperatures, time and catalyst (NaOH) concentration. ao Udeh BA (2017) Biodiesel Production from Waste Vegetable Oil (Sunflower) Obtained from Fried Chicken and Plantain. Biodiesel made from waste vegetable oil is possibly one of the most environmentally friendly fuels available for road vehicles. Yes, the methanol used is derived from petroleum but once it is reclaimed from the glycerol biproduct it's use is only at 14 by volume. Waste sunflower oil sourced from fried chicken and plantain was used for biodiesel production in this study. During the transesterification process, 161 ml of. from waste vegetable oil at a VAT inclusive cost of around 50p per litre. This could generate a large surplus if sold slightly below the current pump price of around 80p per litre for normal diesel. produced from straight vegetable oil, animal oilfats, tallow and waste cooking oil. Todays experiment, we are prepared biodiesel from vegetable oil and waste vegetable oil. BIODIESEL PRODUCTION FROM WASTE SUNFLOWER COOKING OIL AS AN ENVIRONMENTAL RECYCLING PROCESS AND Abstract HOSSAIN, A. Biodiesel production from waste sunflower cooking oil as an environmental recycling process and renewable energy. production of biodiesel from waste frying vegetable oil used catalyst potassium. The production of biodiesel from waste vegetable oil offers a triplefacet solution: economic, environmental and waste management. The new process technologies developed during the last years made it possible to produce biodiesel from recycled frying oils comparable in quality to that of virgin vegetable oil biodiesel with an added attractive advantage of being lower in price. The production of biodiesel from waste vegetable oil offers a triplefacet solution: economic, environmental and waste management. The term waste vegetable oil (WVO) refers to vegetable oil which has been used in food production and which is no longer viable for its intended use. Comparing three options for biodiesel production from waste vegetable oil A. El Sheltawy Department of Chemical Engineering, Faculty of Engineering. biodiesel or waste vegetable oil (WVO) as replacements or supplements for petroleumbased fuel. Both WVO and biodiesel have potential for use on the Williams campus, though their applicability to the school depends on future trends in vehicle usage and fleet replacement. Waste oil type: Bacon grease and other solid greases are not acceptable for biodiesel production since they raise the cloud point and could cause cold weather problems. The First in Spec Biofuels refinery planned for Zone 7 of the Coega Industrial Development Zone (IDZ) will primarily use waste vegetable oil to produce biodiesel and. Producing Biodiesel from Vegetable Oil A Lab Activity Your Students Will Love! All of the information for this activity was found at: Developed by John Jones Glen Rose High School Malvern, AR Heet fuel line heater is 100 methanol. Start with fresh unused oil, NOT with waste vegetable oil (WVO), that also comes later. Start by making a small, 1litre test batch of biodiesel using fresh new oil. You can use a spare blender, or, better, make a simple Testbatch miniprocessor. Hiller machines provide worldclass standards for highperformance decanter centrifuges specially equipped to meet the separation requirements of the Bio Diesel, Waste Vegetable Oil and Animal Fats Processing Industry. With the biodiesel, it is said that there are different types of chemicals. The requirement of the different product along with improving the quality at home is only possible when all the waste vegetable oil can be used in maintaining the cost and make the environment ecofriendly. Production of Biodiesel From Vegetable Oil Lab 5 Transesterification of Vegetable Oil and 5: 54. Biodiesel Education 11, 779 views. Making Biodiesel From Waste Vegetable Oil. Biodiesel is produced by transesterification of triglycerides present in animal fat or vegetable oils, by displacing glycerine with a low molar mass alcohol. Looking for a guide on How To Make Biodiesel Using A Used Cooking Oil? This suitable short video explains precisely how it's done, and will help you get good at drive green. For a biodiesel production rate of 8000 tonnesyr, four flowsheets for continuous alkali and acidcatalyzed processes (IIV) using virgin vegetable oil or waste cooking oil as the raw material were designed and simulated. using waste vegetable oil reduces the need for biodieselproducing crops and the competition with food[3, 5, 14. UCOs have different properties from those of refined and crude vegetable oils [3. The chemical and physical You can also make biodiesel from waste cooking oil, but that is a little more involved, so let's start with the basics. Materials for Making Biodiesel 1 liter of new vegetable oil (e. g, canola oil, corn oil, soybean oil) Biodiesel is produced from vegetable oils, yellow grease, used cooking oils, or animal fats. Biodiesel is produced by transesterificationa process that converts fats and oils into biodiesel and glycerin (a coproduct). Approximately 100 pounds of oil or fat are reacted with 10 pounds of a short. Biodiesel, a renewable fuel produced from animal fats or vegetable oils, is popular among many vehicle owners and fleet managers seeking to reduce emissions and support U. Questions sometimes arise about the viability of fueling vehicle\ s with straight vegetable oil \(SVO\), or waste oils from cooking and other processes. This short course is a must attend for anyone involved in the field of Vegetable Oil Processing and interested in the latest developments in bleaching, hydrogenation, interesterification, deodorization, production of biodiesel and nontrans fats. 3 Disposal All wastes from the reaction should be placed in a bottle labeled for vegetable oil, glycerin and methanol. A separate container will be provided for collection of the biodiesel. production of biodiesel from vegetable oil by transesterification process using continous enzymatic reactor waste vegetable oil 8505. 0084 production of biodiesel from vegetable oil by transesterification through continous enzymatic reactor Biodiesel can be produced from straight vegetable oil, animal oilfats, tallow and waste cooking oil. The process used to convert these oils to Biodiesel is called transesterification. Bio diesel can be produced from straight vegetable oil, animal oilfats, tallow and waste oils. vegetable oils and animal fats, there are concerns that biodiesel feedstock may compete with food supply in the longterm. Hence, the recent focus rely on using waste cooking oil as the substantial feed stocks for biodiesel production. production of biodiesel from waste vegetable oil Shailen Saha 1, J. Fahadullah 4, Himal Barman 5 and Sajal Kumar Bala 6 16 Department pf Mechanical Engineering Chittagong University of Engineering and Technology. The production of biodiesel from waste vegetable oils through its pretreatment followed by transesterification process in presence of methanol was investigated using a KM micromixer reactor. The parameters affecting biodiesel production process such as alcohol to oil molar ratio, catalyst. Refaat ABSTRACT: The production of biodiesel from waste vegetable oil offers a triplefacet solution: economic, environmental and waste management. The new process technologies developed during the last years made it possible to produce biodiesel from recycled frying oils comparable in quality to that of virgin vegetable oil biodiesel with an Biodiesel production from Waste Vegetable Oil This page lists all articles published worldwide in journal, book, magazine or otherwise about biodiesel produciton.